Download Planning and Scheduling - Automated Planning - Lecture Slides and more Slides Computer Science in PDF only on Docsity!

CMSC 722, AI Planning

Planning and Scheduling

Scheduling

• Given:

- actions to perform

- set of resources to use

- time constraints

- e.g., the ones computed by the algorithms in Chapter 14

• Objective:

- allocate times and resources to the actions

• What is a resource?

- Something needed to carry out the action

- Usually represented as a numeric quantity

- Actions modify it in a relative way

- Several concurrent actions may use the same resource

Scheduling Problem

• Scheduling problem

– set of resources and their future availability

– actions and their resource requirements

– constraints

– cost function

• Schedule

– allocations of resources and start times to actions

- must meet the constraints and resource requirements

Actions

• Action a

- resource requirements

- which resources, what quantities

- usually, upper and lower bounds on start and end times

- Start time s ( a ) ∈ [ s (^) min ( a ) ,smax ( a )]

- End time e ( a ) ∈ [ emin ( a ) ,emax ( a )]

• Non-preemptive action: cannot be interrupted

- Duration d ( a ) = e ( a ) – s ( a )

• Preemptive action: can interrupt and resume

- Duration d ( a ) = ∑ (^) i ∈ I d (^) i ( a ) ≤ e ( a ) – s ( a )

- can have constraints on the intervals

Consumable Resources

• A consumable resource is used up (or in some

cases produced) by an action

– e.g., fuel

• Like before, we have total capacity Q i and

current level z i ( t )

• If action requires quantity q of r i

– Decrease zi by q at time s ( a )

– Don’t increase zi at time e ( a )

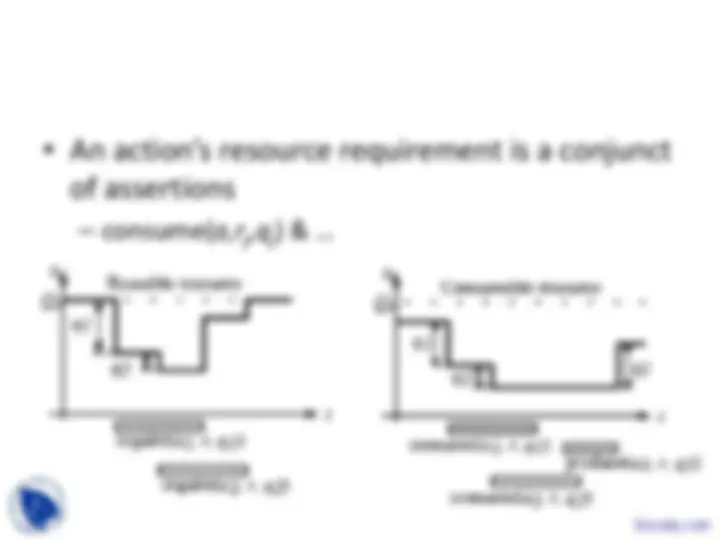

- An action’s resource requirement is a conjunct

of assertions

- consume( a,rj,q (^) j ) & …

- or a disjunct if there are alternatives

- consume( a,rj,q (^) j ) v …

- z (^) i is called the “resource profile” for r (^) i

Costs

• may be fixed

• may be a function of quantity and duration

– e.g., a set-up cost to begin some activity,

plus a run-time cost that’s proportional to the

amount of time

• e.g., suppose a follows b

– cost cr ( a,b ) for a

– duration dr ( a,b ), i.e., s( b ) ≥ e ( a ) + dr ( a,b )

- Objective: minimize some function of the various costs and/or end-times

Single-Stage Machine Scheduling

• Single-stage machine scheduling

- each job is a single action, and can be processed on

any machine

- identical parallel machines

- processing time p (^) j is the same regardless of which machine

- thus we can model all m machines as a single resource of

capacity m

- uniform parallel machines

- machine i has speed( i ); time for j is p (^) j /speed( i )

- unrelated parallel machines

- different time for each combination of job and machine

Multiple-Stage Scheduling

• Multiple-stage scheduling problems

– job contains several actions

– each requires a particular machine

– flow-shop problems:

- each job j consists of exactly m actions { a (^) j 1 , a (^) j 2 , …, a (^) jm }

- each a (^) ji needs to be done on machine i

- actions must be done in order a (^) j 1 , a (^) j 2 , …, a (^) jm

– open-shop problems

- like flow-shop, but the actions can be done in any order

– job-shop problems (general case)

- constraints on the order of actions, and which machine for each action

Notation

- Standard notation for designating machine scheduling problems: α | β | γ α = type of problem: - P (identical), U (uniform), R (unrelated) parallel machines - F (flow shop), O (open shop), J (job shop) β = job characteristics (deadlines, setup times, precedence constraints), empty if there are no constraints γ = the objective function

- Examples:

- Pm | δ j | Σ jw (^) jej

- m identical parallel machines, deadlines on jobs, minimize weighted completion time

- J | prec | makespan

- job shop with arbitrary number of machines, precedence constrants between jobs, minimize the makespan

Complexity

- Most machine scheduling problems are

NP-hard

- Many polynomial-time reductions

Problem types (α in the α|β|γ notation): P - identical parallel machines U - uniform parallel machines R - unrelated parallel machines F - flow shop O - open shop J - job shop

Reductions for α = type of problem Reductions for γ = the objective function

IP Solvers

- Most IP solvers use depth-first branch-and-bound

- Want a solution u that optimizes an objective function f ( u )

- Node selection is guided by a lower bound function L ( u )

- For every node u , L ( u ) ≤ { f ( v ) : v is a solution in the subtree below u }

- Backtrack if L ( u ) ≥ f ( u ), where _u =_ the best solution seen so far

procedure DFBB global u* ← fail; f* ← ∞ call search( r ), where r is the initial node return ( u,f )

procedure search( u ) if u is a solution and f ( u ) < f* then u* ← u ; f* ← f ( u ) else if u has no unvisited children or L ( u ) ≥ f* then do nothing else call search( v ), where v = argmin{ L ( v ) : v is a not-yet-visited child of u }

L ( u ) very similar to A*’s heuristic function f ( u ) = g ( u ) + h ( u )

Main difference: L isn’t broken into f ’s two components g and h

A* can be expressed as a best-first branch-and- bound procedure

Planning as Scheduling

- Some planning problems can be modeled as machine-scheduling problems

- Example: modified version of DWR

- m identical robots, several distinct locations

- job: container-transportation( c,l,l' )

- go to l , load c , go to l' , unload c

- All four tasks to be done by the same robot (which can be any robot)

- release dates, deadlines, durations

- setup time t (^) ijk if robot i does job j after performing job k

- minimize weighted completion time

- Can generalize the example to allow cranes for loading/unloading, and arrangement of containers into piles

- Problem : the machine-scheduling model can’t handle the part I said to ignore

- Can specify a specific robot ri for each job j (^) i , but can’t leave it unspecified

Let’s ignore this for a moment