Download Manufacturing Processes II: Casting Methods, Defects, and Troubleshooting and more Study notes Engineering Dynamics in PDF only on Docsity!

MANUFACTURING PROCESSES II

PROCESS CHARACTERISTICS

IN CASTING METHODS,

DEFECTS AND

TROUBLESHOOTINGS

CASTING

Advantages

- Molten material can flow into very small sections so that intricate shapes can be made by this process. As a result, many other operations, such as machining, forging, and welding, can be minimized.

- Possible to cast practically any material: ferrous or non-ferrous.

- The necessary tools required for casting molds are very simple and inexpensive. As a result, it is the ideal process for production of a small lot.

- There are certain parts (like turbine blades) made from metals and alloys that can only be processed this way. Turbine blades: Casting + Machining.

- Size and weight of the product is not a limitation for the casting process.

Cast Products

- SAND CASTING

- INVESTMENT CASTING

- SHELL MOLDING

- DIE CASTING

- CENTRIFUGAL CASTING

- INGOT CASTING CASTING METHODS 14:47 5

Process parameters for sand casting

SAND CASTING

Pouring temperature Pouring speed Solidification time Mold hardness Moisture content Permeability Mold design Material effect

- Pouring Temperature Tp = Tmelt + (30°C ~ 50°C)

Problem 1: Solidification Time If the diameter (D) is 40 mm and the thickness of the casting (x) is 3 mm, please calculate the volume, surface area, and solidification time of this cylindrical casting part (C= 22 and n= 2).

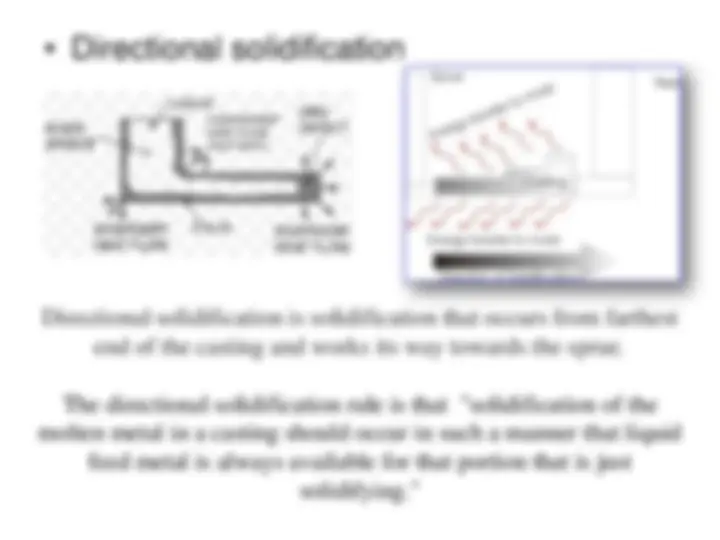

- Directional solidification

Directional solidification is solidification that occurs from farthest

end of the casting and works its way towards the sprue.

The directional solidification rule is that "solidification of the

molten metal in a casting should occur in such a manner that liquid

feed metal is always available for that portion that is just

solidifying."

Another way to describe directional solidification is

that the casting should -- "cool and solidify

progressively from thin sections to heavy sections with

constant metal feed into the heavy sections."

In the figure, the heaviest section is the 2.5" diameter

center hub. The mold should be designed so that the

hub section will solidify last and have good metal feed

through the entire cooling process.

- Directional solidification

Process parameters for die casting

DIE CASTING

Pouring temperature Injection pressure Die temperature Plunger velocity Die cooling system Filling time Flow rate Die design Die surface coating Material effect

- Die Temperature

- Low die temperature produce misruns

- High die temperature results the mold erosion

- Pouring Temperature

- High pouring temperature reduces the die life

- High pouring temperature increases shrinkage problems

- High pouring temperature induces longer cycle time

- High pouring temperature increases the rate of gas

solubility in the metal