Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

An in-depth exploration of the concepts of phases, equilibrium phase diagrams, and solubility in the context of the iron-carbon system. It covers topics such as single-phase solids (ferrite, austenite, delta-ferrite, cementite), phase transitions, and three-phase reactions (eutectic and eutectoid). The document also discusses the importance of iron-carbon diagrams in materials science and engineering.

Typology: Lecture notes

1 / 41

This page cannot be seen from the preview

Don't miss anything!

TEMPERATURE–COMPOSITION DIAGRAMS

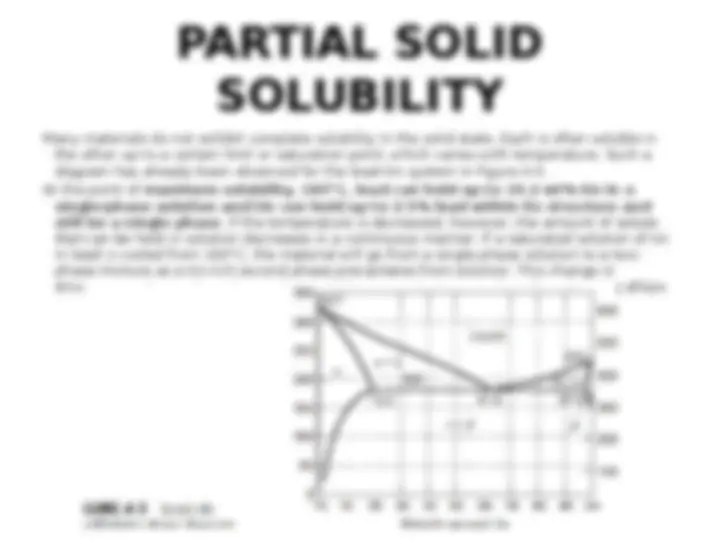

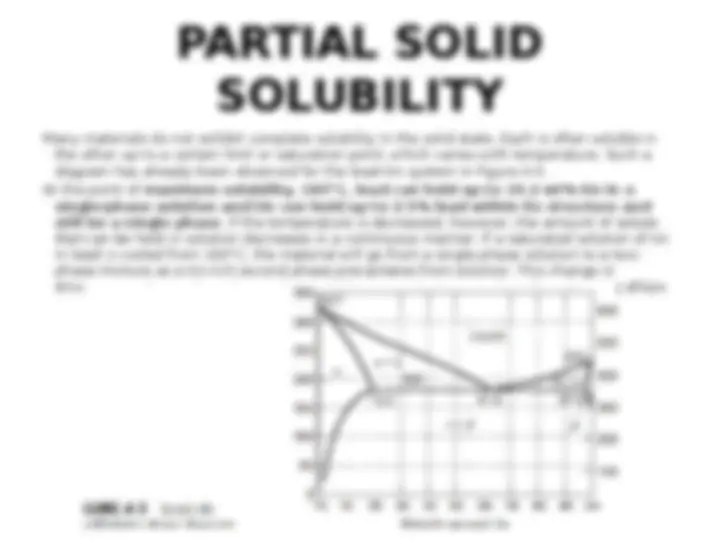

Both pure materials have a distinct melting point, below which they appear as a pure solid. As we move away from a pure material, we often encounter a single-phase solid solution, in which a small amount of one component is dissolved and dispersed throughout the other. If there is a limit to this solubility, there will be a line in the phase diagram, known as a solvus line , denoting the conditions where the single-phase solid solution becomes a two-phase mixture. Figure 4-5 presents the equilibrium phase diagram for the lead– tin system, using the conventional notation in which Greek letters are used to denote the various single-phase solids. The upper portion of the diagram closely resembles the salt–water diagram, but the partial solubility of one material in the other can be observed on both ends of the diagram.

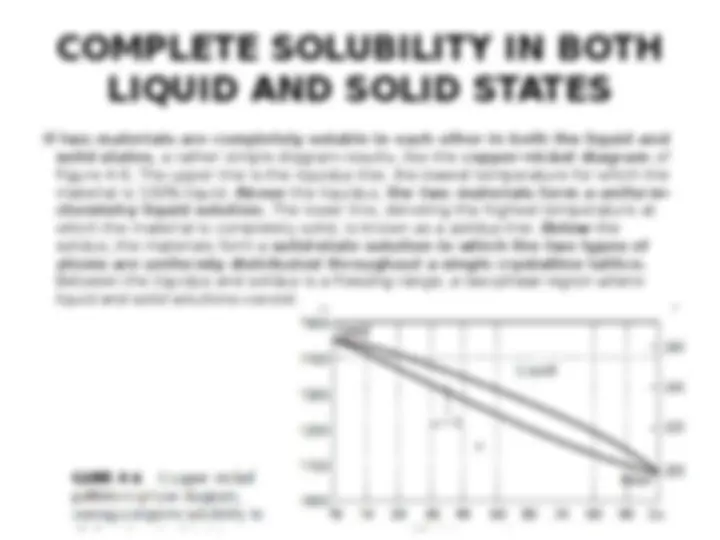

COMPLETE SOLUBILITY IN BOTH LIQUID AND SOLID STATES If two materials are completely soluble in each other in both the liquid and solid states , a rather simple diagram results, like the copper–nickel diagram of Figure 4-6. The upper line is the liquidus line, the lowest temperature for which the material is 100% liquid. Above the liquidus, the two materials form a uniform- chemistry liquid solution. The lower line, denoting the highest temperature at which the material is completely solid, is known as a solidus line. Below the solidus, the materials form a solid-state solution in which the two types of atoms are uniformly distributed throughout a single crystalline lattice. Between the liquidus and solidus is a freezing range, a two-phase region where liquid and solid solutions coexist.

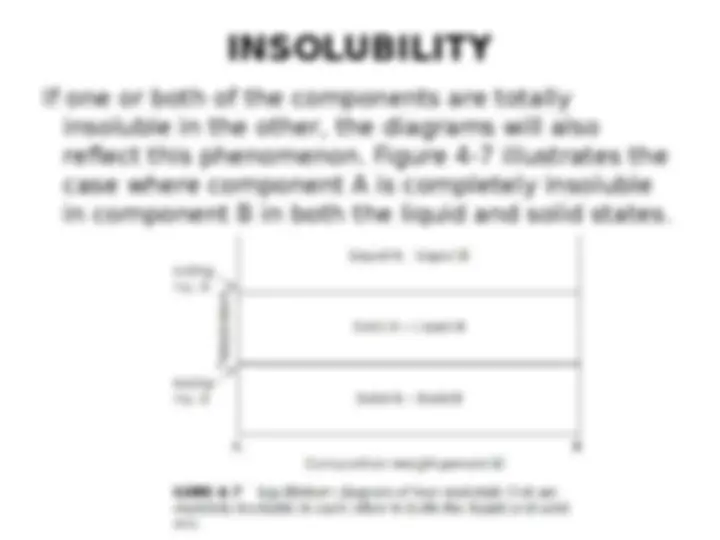

INSOLUBILITY If one or both of the components are totally insoluble in the other, the diagrams will also reflect this phenomenon. Figure 4-7 illustrates the case where component A is completely insoluble in component B in both the liquid and solid states.

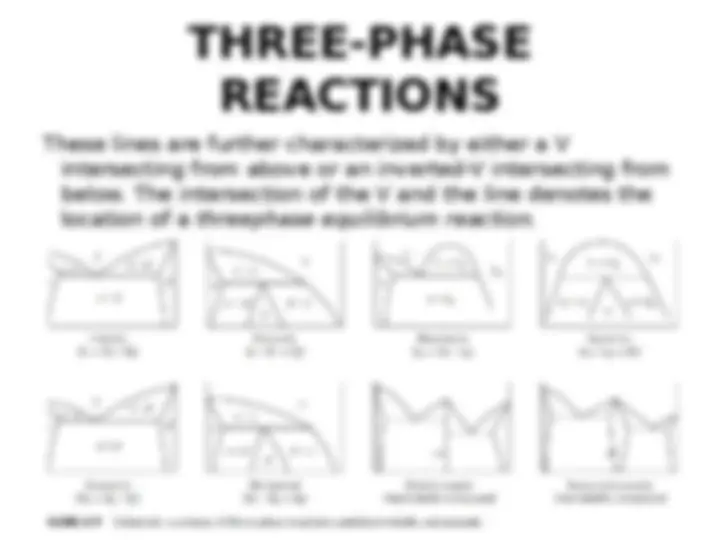

These lines are further characterized by either a V intersecting from above or an inverted-V intersecting from below. The intersection of the V and the line denotes the location of a threephase equilibrium reaction.

One common type of three-phase reaction, known as a eutectic, has already been observed in Figures below

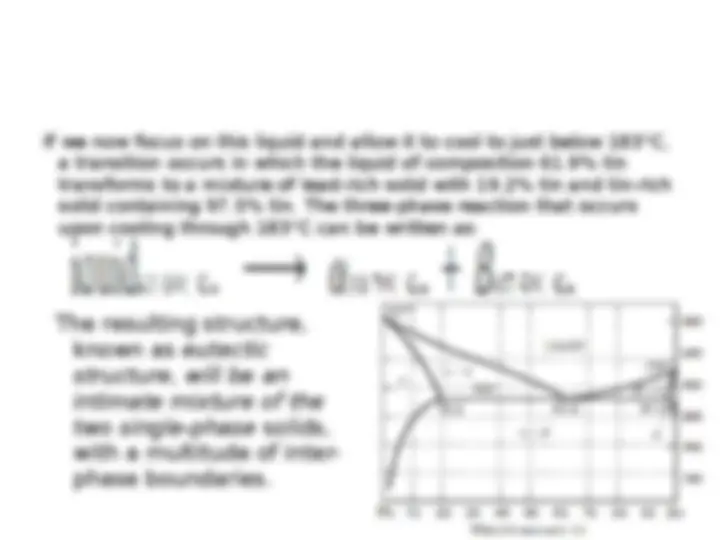

Alloys with the eutectic composition have the lowest melting point of all neighboring alloys and generally possess relatively high strength. For these reasons, they are often used as casting alloys or as filler material in soldering or brazing operations. The eutectic reaction can be written in the general form of:

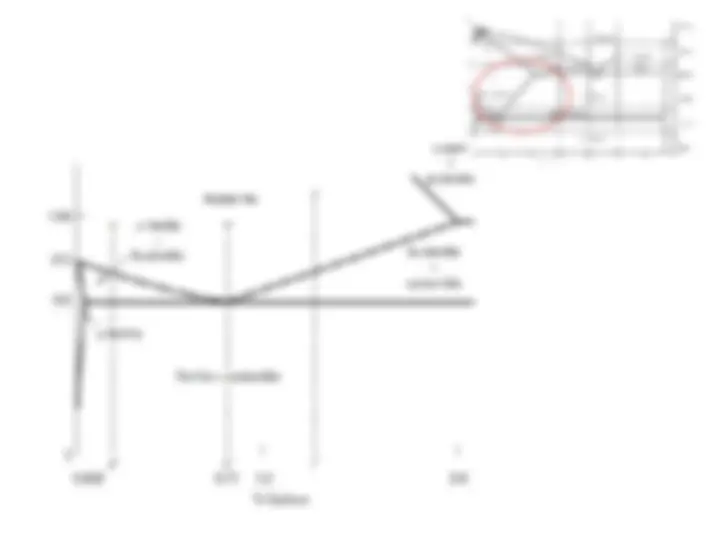

THE IRON CARBON DIAGRAM

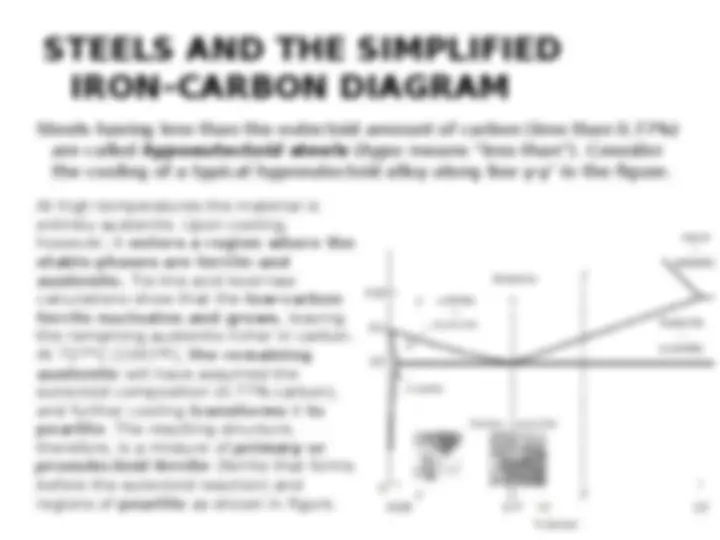

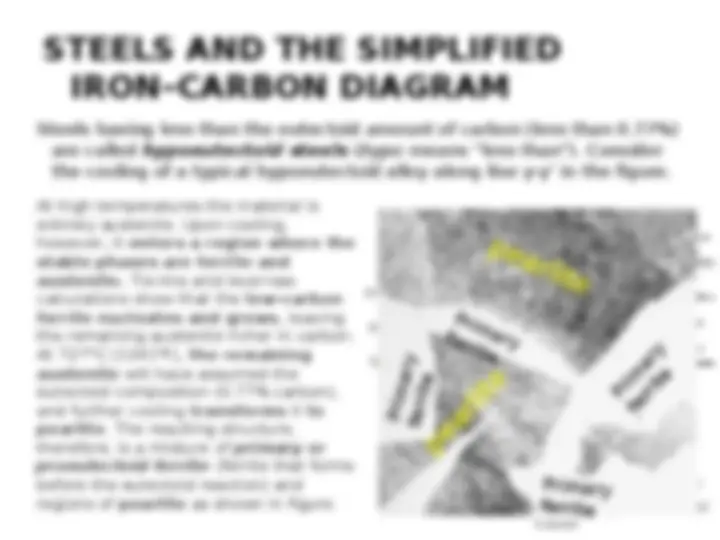

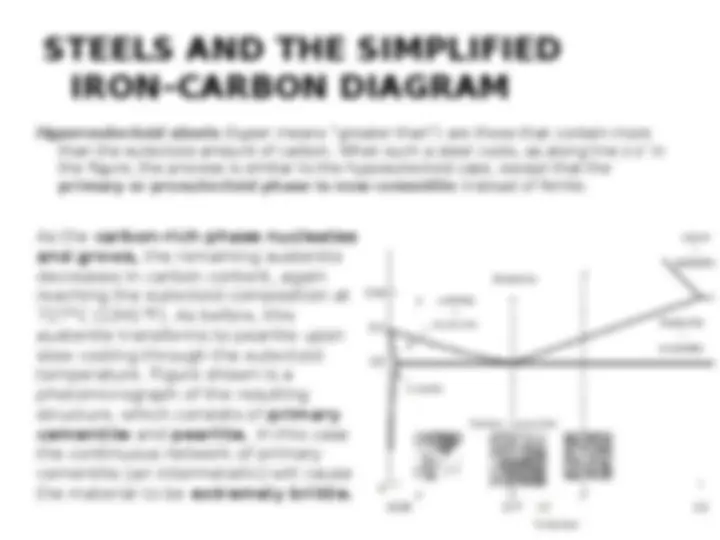

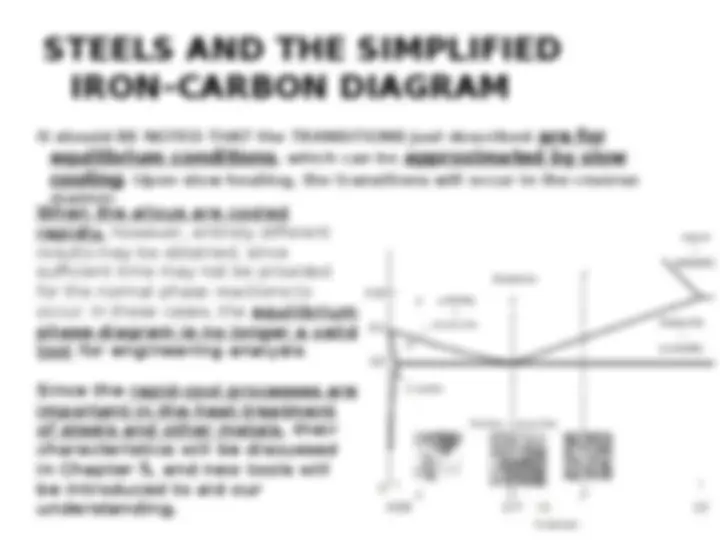

IRON–CARBON EQUILIBRIUM DIAGRAM Steel, composed primarily of iron and carbon, is clearly the most important of the engineering metals. For this reason, the iron– carbon equilibrium diagram assumes special importance. The diagram most frequently encountered, however, is not the full iron–carbon diagram but the iron–iron carbide diagram. The iron-carbon equilibrium phase diagram. Single phases are: ferrite, austenite, delta-ferrite, cementite