Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

Exam questions for the unit 64ee3013: control engineering of the beng (hons) electrical and electronic engineering program at manchester metropolitan university. The questions cover topics such as root locus analysis, closed-loop transient performance, process control models, and pole placement controllers.

Typology: Exams

1 / 9

This page cannot be seen from the preview

Don't miss anything!

Exam ination for th e BEng (H O NS) ELECTR ICA LAND ELECTR O NIC ENGINEER ING (FULL- TIME/PA R T TIME) YEA R FO UR /FIVE

Monday 21 May 2001

2.00 pm to 5.00 pm

Instructions to Candidates

A nsw er FIVE questions w ith not m ore th an th ree from eith er section.

Figure Q 1(a) and Jury Contours are provided on separate sh eets.

Break dow n of m ark s for each question are sh ow n in square parenth eses.

(i) A ssess th e dam ping ratio of th e com plex poles. [3] (ii) Find th e 5% settling tim e associated w ith th e poles. [2] (iii) Locate th e position of closed loop zeros and discuss th eir effect on system response. [3] (iv) Can th e poles be regarded as dom inant? [2] (v) Find th e gain to cause th e system to b e com e unstab le on closed loop. [4]

Sh ow any construction w ork on figure Q 1(a) and h and th is in w ith your answ er book.

(b ) W ith K = 0.8, find th e system steady state error to a unit step reference input.

[6]

ss s

K s

s +

Figure Q 1(b )

Section A

− s

e Gs

s and its open-

loop frequency response is sh ow n in figure Q 3.

(i) Explain w h y such m odels are used in process controland sk etch th e process response to a unit step input. [3] (ii) Verify by calculation th at th e ph ase cross-over frequency is approxim ately 1.84 rs-1. [2] (iii) Verify by m easurem ents on th e Nyquist diagram th at th e gain m argin is approxim ately 2.5. [2] (iv) D e scrib e a m eth od by w h ich th ese m easurem ents m ay be approxim ated in closed loop and explain h ow th is can form th e b asis for self-tuning. [5] (v) D iscuss in qualitative term s th e effect of an increase in process dead tim e on th e gain m argin. [2]

(c) Explain w h at is m eant by feedforw ard control. W h at advantages m ay be gained by its use?W h y in practice m ust feedforw ard controlalw ays be used togeth er w ith fe e d b ack control? [6]

Figure Q

u(t) x(t)

x(t)

x (t)

x(t)

2

1

2

1

Th e state variab le, x 1 (t), represents m otor speed (radian per second) and th e input u(t), is m easured in volt. (i) W rite dow n th e differentialequation representing x 2 (t)

(i) Find th e system ch aracteristic equation. [6] (ii) Find th e system dam ping ratio and undam ped naturalfrequency. [2] (iii) D raw a sk etch of th e response of th e state variab les x 1 (t)and x 2 (t)to a unit step reference input over th e first 5 seconds of th e response. Sh ow th e steady state values and give an indication of k ey tim e dom ain perform ance criteria. [3]

Figure Q

∑ (^) x^ • (t) = Ax(t) + Bu(t)

(a) D iscuss th e im plications for controller design if th e plant contains unstab le poles or zeros outside th e unit circle. [6] (b ) Th e continuous-tim e transfer function of th e plant is given as

ss

Gp s. W h en a sam pling intervalof 0.5 seconds is used,

sh ow th at ( 1 )( 0. 607 )

z z

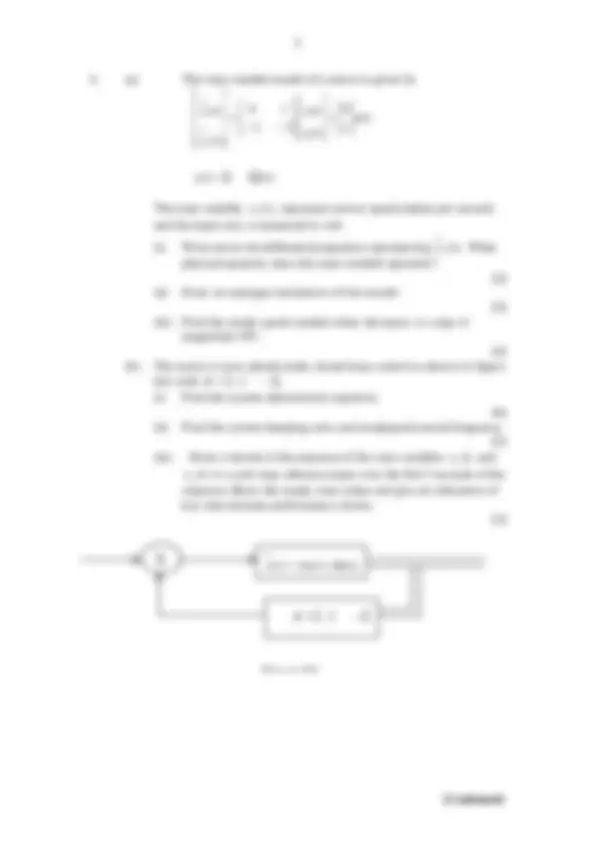

G z z p. Design a pole-placem ent controller

to give a closed-loop system w ith a second-order response w ith a dam ping ratio of 0.7, 5% settling tim e of 4 s and zero steady-state error for step inputs. [14]

R (z) (^) D (z) Gp(z) Y(z

Figure Q

(i) Estim ate th e param eters of a first-order m odelth at fits th e data using least squares tech nique. [8 ] (ii) Explain h ow th e estim ated m odelcan b e validated. [6 ]

k 0 1 2 3 4 5 u(k ) 1 1 0 -1 -1 1 y(k ) 0 0. 2 0. 36 0. 288 0. 03 -0. 176

(z .z. )

G(z). 11 028

= (^2) − + is to b e controlled in unity fe e d b ack configuration such th at th e output

Y(z) follow s th e reference input R (z).

designed to m eet th e requirem ent. [8] (b ) If th e actualprocess gain is 10% h igh er th an th at indicated by th e m odel used in (a), estim ate th e steady-state offset th at m ay result w h en controlled in closed-loop using th e controller designed in (a). [5] (c) Sh ow h ow th e offset can b e rem oved. [3]

(d) Com m ent on th e nature of controlsignalgenerated by a m inim um variance controller and sh ow b riefly h ow excessive controlaction can b e reduced. [4]

Table Q